Thepa

Re sebelisa thepa e tsoang kantle ho naha le "Three High" e tsebahalang ka har'a naha ea tungsten carbide e tsoang ho bahlahisi ba tsebahalang joalo ka lisebelisoa tse tala.

Lisebelisoa tsa Premium

Lintho Tse Tloaelehileng

Re amohela ts'ebetso ea machaba ea tlhahiso ea carbide e tsoetseng pele e tsoetseng pele e tsoetseng pele ho etsa lihlahisoa tsa boleng bo holimo tsa alloy.

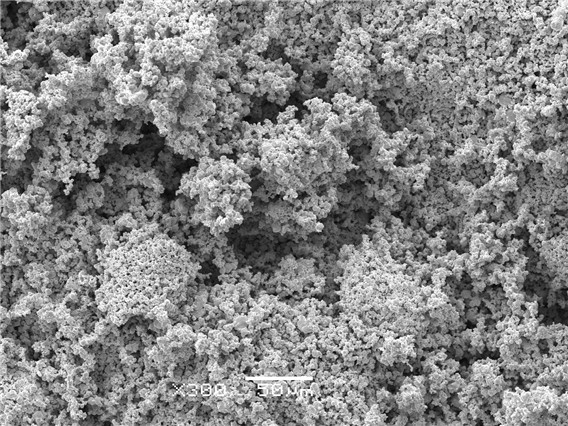

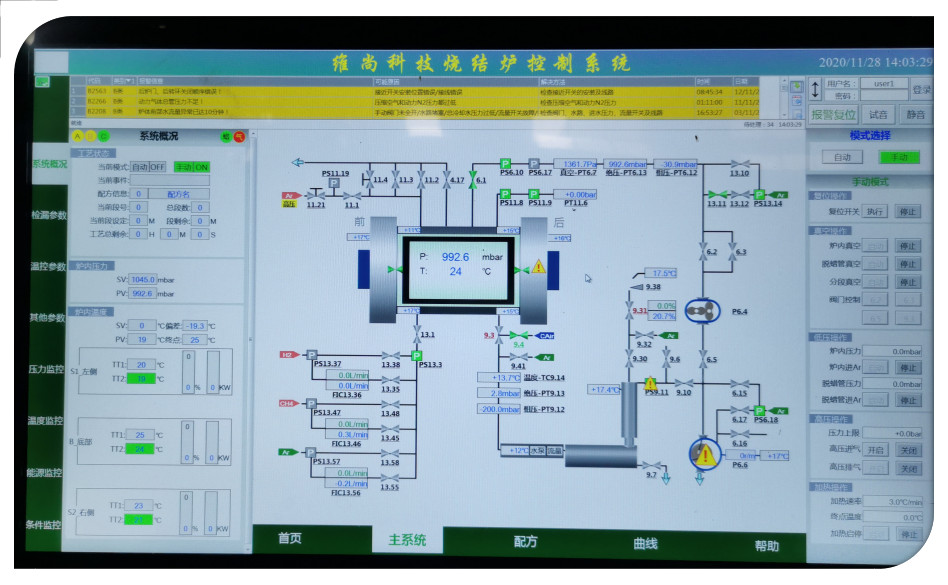

Seboka sa rona sa ho lokisa tšilo e kopantsoeng ea bolo e ntlafalitsoe ho fihlela taolo e bohlale le e ikemetseng.Ka sistimi e itirisang ea taolo, re laola liparamente tse kang lebelo la ho potoloha, nako, mocheso, joalo-joalo. Liphoso life kapa life li hlokomelisoa ka potlako, 'me tlhahlobo e felletseng ea data e etsoa ho tsoela pele ho ntlafatsa maemo a taolo ea ts'ebetso.

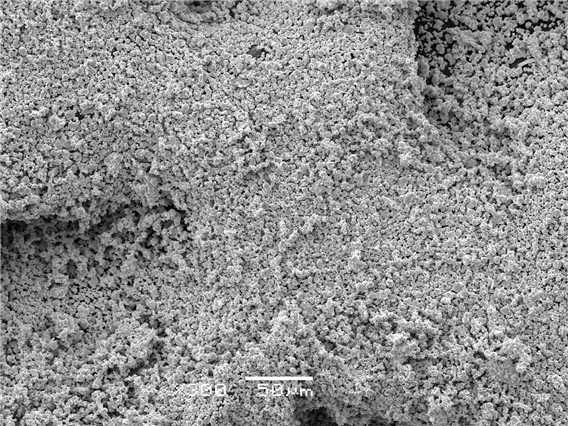

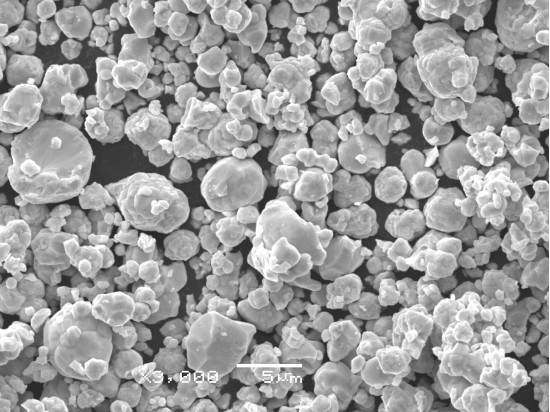

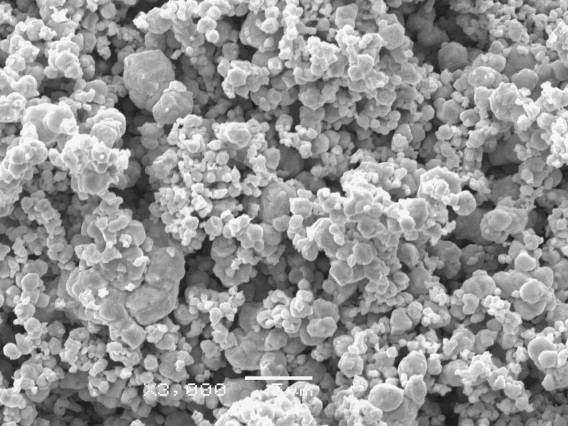

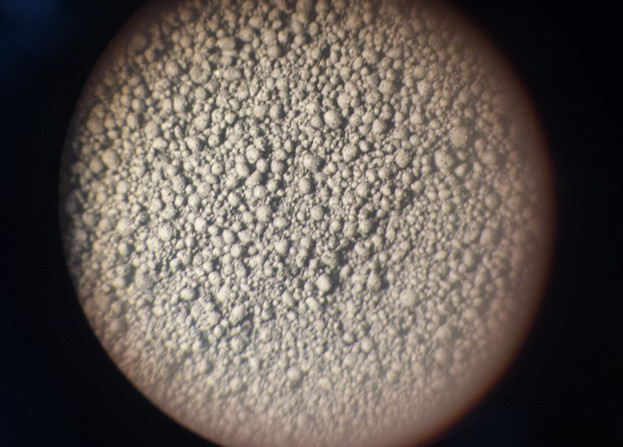

Re sebelisa theknoloji e tsoetseng pele ea ho omisa granulation tech-noology, e bapisoang le granulation ea setso, ka nepo e arola moea le lerōle, e bakang likaroloana tsa phofo tse lekanang ka boholo le boleng bo ts'oanang.

Seboka sa Compaction le Molding:

Ts'ebetsong ea rona ea ho kopanya, re sebelisa mechine e tsoetseng pele e kenyelletsang mochine oa khatiso oa TPA oa lithane tse 60 le mochine oa khatiso oa hydraulic oa lithane tse 100.Sena se fella ka bongata ba lihlahisoa tse tala tse ajoang ka mokhoa o ts'oanang le ho nepahala ho holimo litekanyong tsa sehlahisoa.Seboka sena se boloka moea o motle oa khatello ea moea, mocheso oa selemo ho pota le taolo ea mongobo, hammoho le mehato ea ho hloekisa moea ho netefatsa tikoloho ea tlhahiso e se nang tšilafalo le boleng ba lihlahisoa ho pholletsa le ts'ebetso ea tlhahiso.

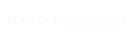

Lilemong tse 50 tse fetileng, theknoloji e entsoeng ka samente ea carbide sintering e 'nile ea e-ba le phetoho e tsoelang pele ho tloha ho libopi tsa hydrogen ho ea ho libopi tsa vacuum,' me qetellong ho ea ho libopi tsa khatello.Sintering-assisted sintering e hlahile e le mokhoa o ka pele oa alloy sintering lefatšeng ka bophara.Mokhoa ona o kopanya debinding, vacuum sintering, le khatello ea sintering mohatong o le mong, ho fokotsa porosity ea sehlahisoa le ho finyella boemo ba alloy density ho tšoana le thepa e teteaneng ka ho feletseng.

Mehato e Robong ea Taolo ea Boleng ba Tlhahiso ea Alloy:

1. Teko ea Lits'ebetso tsa Raw Material's Chemical and Physical Properties

2. Teko ea Ts'ebetso ea Teko ea Raw Material Ball Milling

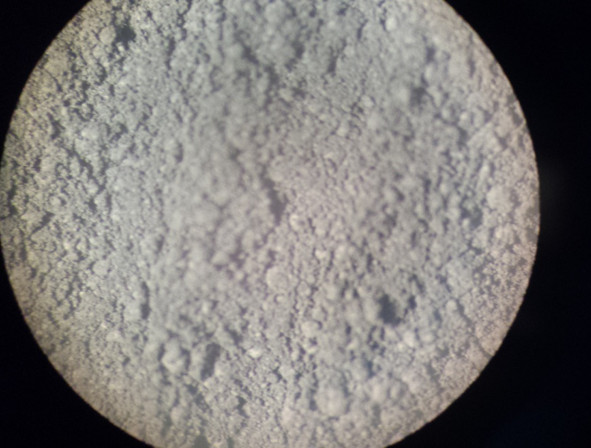

3. Sampling le Teko ea Thepa ea 'Mele ea Mixed Ball-Milled Materials

4. Ho Itsebahatsa ka Sampling le Teko ea Thepa ea 'Mele ea Mixed Spray-Milled Materials.

5. Teko ea Pele ea Ts'ebetso ea Compaction Calibration le Molding

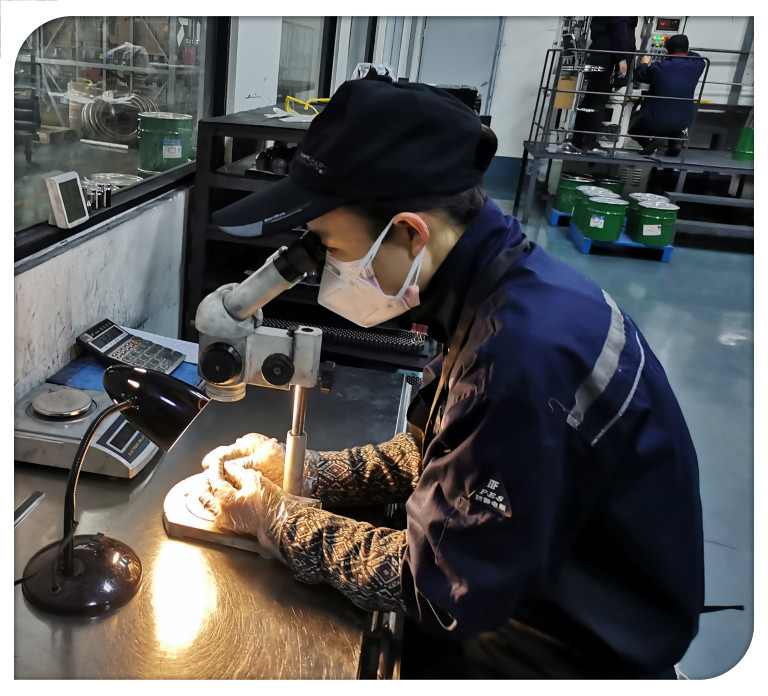

6. Ho itlhahloba ka Boleng ba Tlhahiso nakong ea Compaction

7. Ho Hlahlobisisa Boleng ba Boleng ka Basebetsi ba Boleng ba Compaction

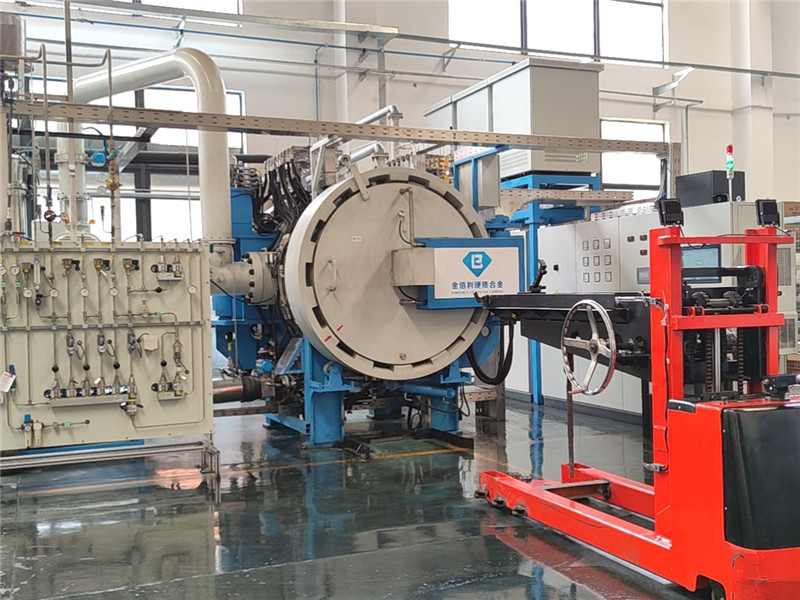

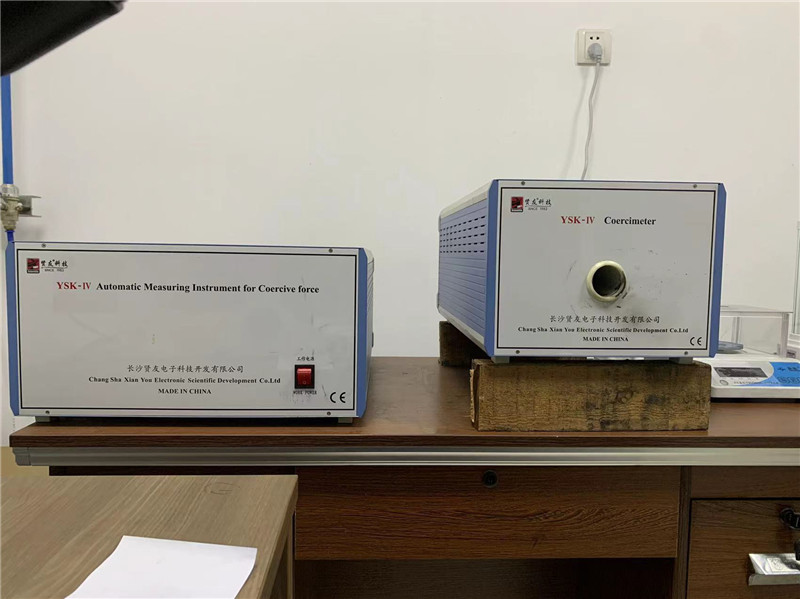

8. Ho lekoa ha Lintho tsa 'Mele le Mechini ea Lihlahisoa tsa Sintered Finished

9. Tlhahlobo ea Mefuta e Felletseng ea Lihlahisoa, Litekanyo, Ponahalo, le Mefokolo.