Lisebelisoa

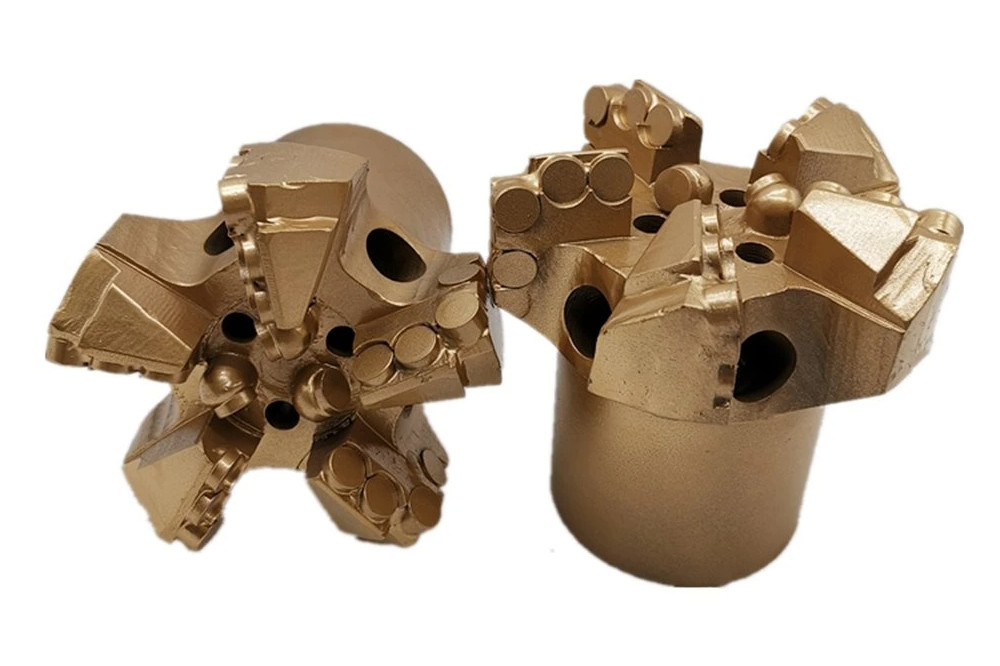

Lisebelisoa tsa motheo tsa lipoleiti tse kopantsoeng tsa litaemane li fumana lits'ebetso likarolong tse fapaneng tse ipapisitseng le thepa ea tsona, ho kenyelletsa empa e sa felle ho:

Lisebelisoa tsa ho kuta le ho sila:

Lisebelisoa tsa motheo tsa lipoleiti tse kopantsoeng tsa litaemane li atisa ho sebelisoa ho etsa lisebelisoa tsa ho seha le ho sila tse kang mabili a sila le li-blades.Thepa ea motheo e ka susumetsa ho tiea ha sesebelisoa, ho tšoarella, le ho ikamahanya le maemo.

Lisebelisoa tsa ho Felisa Mocheso:

Thermal conductivity ea thepa ea motheo ke ea bohlokoa bakeng sa lisebelisoa tsa ho senya mocheso.Lipoleiti tse kopantsoeng tsa daemane li ka sebetsa e le lisebelisoa tsa substrate bakeng sa lithako tsa mocheso tse sebetsang hantle ho tsamaisa mocheso hantle.

Sephutheloana sa Elektronike:

Lisebelisoa tsa motheo tsa lipoleiti tse kopantsoeng tsa litaemane li sebelisoa ho paka likarolo tsa elektronike tse matla a phahameng ho ntlafatsa bokhoni ba ho qhala mocheso le ho sireletsa likarolo tsa elektroniki.

Liteko tsa Khatello e Phahameng:

Tekong ea khatello e phahameng, thepa ea motheo e ka ba karolo ea lisele tse nang le khatello e phahameng, e etsisang thepa ea thepa tlas'a maemo a feteletseng a khatello e phahameng.

Litšobotsi

Litšobotsi tsa lisebelisoa tsa motheo ka lipoleiti tse nang le litaemane tse kopantsoeng ka ho toba li ama ts'ebetso le ts'ebeliso ea thepa.Mona ke tse ling tsa litšobotsi tse ka bang teng:

Thermal Conductivity:

Mocheso oa mocheso oa thepa ea motheo o ama matla a ho tsamaisa mocheso oa poleiti eohle e kopantsoeng.Mocheso o phahameng oa mocheso o thusa ho fetisetsa mocheso kapele ho tikoloho e potolohileng.

Matla a Mechini:

Thepa ea motheo e hloka ho ba le matla a lekaneng a mochini ho netefatsa botsitso le ho tšoarella ha poleiti eohle e kopaneng nakong ea ho seha, ho sila le lits'ebetso tse ling.

Wear Resistance:

Thepa ea motheo e lokela ho ba le khanyetso e itseng ea ho roala ho mamella likhohlano tse phahameng le maemo a khatello ea maikutlo nakong ea ho itšeha, ho sila le ts'ebetso e ts'oanang.

Chemical Stability:

Thepa ea motheo e hloka ho lula e tsitsitse libakeng tse fapaneng 'me e be khahlanong le ho bola ha lik'hemik'hale ho netefatsa ts'ebetso ea nako e telele.

Matla a Bonding:

Thepa ea motheo e hloka matla a matle a tlamahano le likristale tsa daemane ho netefatsa botsitso le ho ts'epahala ha poleiti eohle e kopaneng.

Ho ikamahanya le maemo:

Ts'ebetso ea lisebelisoa tsa motheo e lokela ho ts'oana le thepa ea likristale tsa daemane ho fihlela ts'ebetso e nepahetseng lits'ebetsong tse ikhethileng.

Ka kopo hlokomela hore ho na le mefuta e mengata e fapaneng ea lisebelisoa tsa motheo ka lipoleiti tse kopantsoeng tsa litaemane, e 'ngoe le e' ngoe e na le thepa le lisebelisoa tse fapaneng.Ka hona, lits'ebetsong tse khethehileng, lisebelisoa tsa motheo tse loketseng li lokela ho khethoa ho latela litlhoko

Boitsebiso ba Lintho

| Mephato | Tekano(g/cm³)±0.1 | Ho thatafala(HRA)±1.0 | Cabalt(KA/m)±0.5 | TRS (MPa) | E khothalelitsoeng Kopo |

| KD603 | 13.95 | 85.5 | 4.5-6.0 | 2700 | E loketse lisebelisoa tsa motheo tsa poleiti ea litaemane tse sebelisoang ho jeoloji, libaka tsa mashala le lits'ebetso tse ts'oanang. |

| KD451 | 14.2 | 88.5 | 10.0-11.5 | 3000 | E loketse lisebelisoa tsa motheo tsa poleiti ea daemane tse sebelisoang sebakeng sa oli. |

| K452 | 14.2 | 87.5 | 6.8-8.8 | 3000 | E loketse lisebelisoa tsa motheo tsa PDC blade |

| KD352 | 14.42 | 87.8 | 7.0-9.0 | 3000 | E loketse lisebelisoa tsa motheo tsa PDC blade. |

Tlhaloso ea Sehlahisoa

| Mofuta | Litekanyo | |||

| Diameter (mm) | Bophahamo (mm) | |||

| KY12650 | 12.6 | 5.0 | |

| KY13842 | 13.8 | 4.2 | ||

| KY14136 | 14.1 | 3.6 | ||

| KY14439 | 14.4 | 3.9 | ||

| YT145273 | 14.52 | 7.3 | |

| YT17812 | 17.8 | 12.0 | ||

| YT21519 | 21.5 | 19 | ||

| YT26014 | 26.0 | 14 | ||

| PT27250 | 27.2 | 5.0 | |

| PT35041 | 35.0 | 4.1 | ||

| PT50545 | 50.5 | 4.5 | ||

| E khona ho iketsetsa ho latela boholo le tlhokahalo ea sebopeho | ||||

mabapi le rona

Kimberly Carbide e sebelisa lisebelisoa tse tsoetseng pele tsa indasteri, sistimi e tsoetseng pele ea taolo, le bokhoni bo ikhethang ba boqapi ho fana ka bareki ba lefats'e lefapheng la mashala ka bokhabane bo matla ba thekenoloji le ts'ebetso e felletseng ea Three-Dimensional VIK.Lihlahisoa li tšepahala ka boleng 'me li bonts'a ts'ebetso e phahameng, e tsamaeang le matla a makatsang a theknoloji a se nang lithaka.Khamphani e khona ho hlahisa lihlahisoa ho latela litlhoko tsa bareki, hammoho le ntlafatso e tsoelang pele le tataiso ea tekheniki.